In most cases, we recommend a 12v 45 lbs trolling motor. As for the length, most owners opt for the 42″ length variant.

Author: admin

Can I take my boat to any CRI dealer for service and support?

Yes! Understanding that you and your boat may relocate during the course of your ownership, we invite you to take your boat to any of our dealers for service and support. To find a dealer, simply use our online locator, and reach out the desired dealer to schedule service.

On the topic of awesome service and support, we always welcome your thoughts and ask that you share your opinion by completing our dealer feedback and review form found below.

How do I operate my aerated bait well?

This article is intended to provide general operational instruction for aerated bait wells found on Sea Born, Sundance, and Spyder boats.

Operation

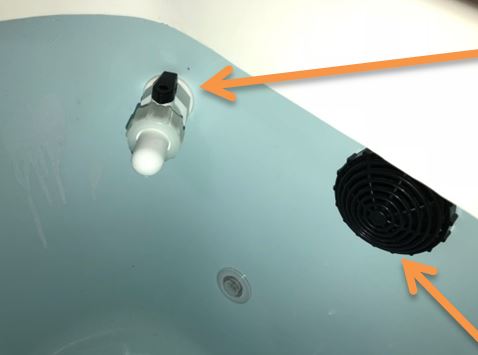

Locate the rubber drain stopper(s) found inside the blue accessories pouch. See Figure 1

Next, open the desired bait well(s) and locate the drain opening at the bottom. Prior to starting the flow of water, firmly place the stopper in the bottom of the well. Next, locate the aerator spray head found near the top of the well. See Figure 2

Notice the spray head has a small black lever on top which may be turned 90° to the left which is the off position. To open the valve to the “on” position and allow the flow of water, turn the spray head to the center or inline with the spray head body. See Figure 3

To start the flow of water, from the console instrument panel, turn the Bait Well into the on position. Immediately, water should begin to fill the well chamber. Once water reaches the level of the overflow screen, located beside the spray head, water will begin draining overboard through the thru-hull drains located on the transom. See Figure 4

Regarding baits, most need less water changes per hour than the pump will supply. For example, shrimp and crustaceans need approximately 5 changes whereas fin baits need 7 to 10. Unless the operator has reduced the fill rate, the pump head will supply about double the needed amount. Given this, typical use in most cases would position the fill lever at a 45 degree angle.

Regarding Dry Storage

If the lever is in the open position and the pump is turned off, water from the high speed pick-ups will flow into the well when the boat is running. If you intend to use the well for dry storage or as a drink cooler remember to close the lever to the 90 degree off position.

How to clean the caulk in my boat’s seams?

The “caulk” used in your CRI boat is a UV resistant, polymer sealant made specifically for permanent elastic seals. Occasionally you may notice what appears to be mildew forming on the surface. This is actually hydrocarbons primarily from air pollution (typically auto exhaust) that forms a film on the surface of the sealant.

To clean, use mineral spirits and a soft cotton rag to scrub the sealant surface. Several applications may be required. Once clean, wash the area with a large amount of a degreasing liquid detergent (i.e. ”Dawn”) and plenty of fresh water.

Remember to use personal protective equipment such as solvent resistant gloves and protective eyewear.

Product Information

Sikaflex®-521 UV

Sikaflex®-521 UV is a multi-purpose, UV resistant, non-sag, elastic, one-part silane-terminated polymer sealant, which cures on exposure to atmospheric moisture to form a durable elastomer. Sikaflex-521 UV is solvent and isocyanate free.

Use

Sikaflex®-521 UV bonds well to a wide variety of substrates without the need for special pre-treatment and is suitable for making permanent, high strength elastic seals. Compatible substrate materials include wood, metals, (particularly aluminum including anodized components), sheet steels (including phosphated, chromated and zinc-plated components), metal primers and paint coatings (two-part systems), ceramic materials, fiberglass, plastics and glass.

Characteristics and Advantages

- Very low VOC/solvent free

- Silicone and PVC-free

- Isocyanate-free

- High electrical resistance

- Resistant to aging and weathering

How do I request warranty service?

Warranty Process

In order to request warranty services, you must first contact your local Sea Born, Sundance, or Spyder dealer. The dealer will work with you to schedule an appointment to review your issues and determine if grounds exist for a warranty claim. In the event warranty work is required, your independent CRI dealer will then submit a warranty service request (“Claim Request”) on your behalf. Once submitted and reviewed by factory personnel, your request will be approved, adjusted or denied.

:: NOTE: BEFORE YOU SEEK WARRANTY SERVICES OR REPAIRS YOU MUST FIRST REGISTER YOUR BOAT. NOTE: FACTORY PERSONNEL ARE UNABLE TO ASSIST OR TO PROVIDE THE STATUS OF A REQUEST WITHOUT A DEALER SUPPLIED CLAIM NUMBER ::

[ Download – Limited Warranty Information – Composite Research, Inc. ]

Warranty Information

This Limited Warranty also limits and alters your remedies. This Limited Warranty shall be the sole and exclusive remedy of any person or entity for any claim, whether that claim sounds in contract, tort, or in any other basis for recovery. Composite Research, shall not be liable to any person or entity for any consequential, special, or incidental damages, lost profits, inconvenience, or any other loss or damages, except as provided in this limited warranty.

Composite Research Limited Warranty

Transferable 10 Year Limited Hull Warranty

Transferable Option

This Limited Warranty commences on the date of delivery to the original retail purchaser or when the boat has been operated for twenty-five (25) hours or on the first day of the twenty-fifth (25 th ) month from the date of shipment from Composite Research, Inc. to an authorized Composite Research, Inc. dealer, whichever occurs first.

Exceptions: The 10 Year warranty does not cover the gel coat nor any other components fastened or applied to the dash, hull or deck. Gel coat discoloration, blisters, and cracks are not considered structural defects. Gel coat along with installed components are warranted separately under the Composite Research, Inc. Nonstructural warranty listed below.

Time limitations shall run from the date of delivery to the original retail purchaser in the United States of America.

Registration and Transfer of Limited Warranty

3 Year Nonstructural Limited Fiberglass Small Parts Warranty

1 Year Nonstructural Limited Systems Warranty

No part of this warranty covers or implies coverage for loss of use.

To validate this warranty, the Warranty Registration Form (https://www.criboats.com/owner-warranty-registration/) provided by Composite Research, Inc. must be within (30) thirty days after the original purchase date of the vessel. Reception of the warranty registration card is a condition precedent to this warranty.

We warrant the boat hull and bottom construction for a period of One Hundred Twenty (120) months from date of original purchase, except as noted below, against “delamination” or separation CAUSED BY MANUFACTURER’S DEFECT (see definition of “delamination” for more specific information), providing that the integrity of the hull or floor has not been broken (such as with impact damage) or has been worn through.

Origin Date: Composite Research at it’s sole discretion shall reserve the right to reject any warranty repair, replacement, or defect of non-structural limited systems whereby the vessel has been delivered to a dealer and not sold for a period greater than 1 year from the original delivery date.

One-Year Exterior Cosmetic Gelcoat Limited Warranty

1. Up to six (6) months from the warranty commencement date, Composite Research will pay 100% of the repair costs.

2. After six (6) months but up to one (1) year from the warranty commencement date, Composite Research will pay 50% of the repair costs.

3. After one (1) year from the warranty commencement date, Composite Research will pay 0% of the repair costs.

Definition of Delamination

What is Not Covered ‐ This Warranty Does Not Apply to:

- A Hull, component, or other product that has been repaired without authorization of Composite Research or that has been altered in any way that affects its use and operation;

- Expenses related to inspection or survey or warranty service for hauling out, transportation to and from any dealer or Composite Research factory, towing or storage charges, inconvenience or loss of time or income;

- Note: It is the owner’s responsibility to provide transportation of the boat both to the service location and its return after repairs are completed. The service location will be determined by Composite Research;

- Any Composite Research Boat initially sold at retail by a party other than an authorized Composite Research dealer;

- Blistering, discoloring, cracking, or crazing of the Gelcoat finish or other surface finishes;

- Optional Accessories or their removal or installation including but not limited to, Bimini Tops, Swim Platforms, or other items not installed by Composite Research or components installed by Marine Dealers or Customers;

- Engines or Engine installation or removal;

- Outdrives, Jet drives, Propellers, Controls, Engine Brackets, Stereos, Depth Finders, GPS units, Trolling Motors, Batteries, Outrigger Bases, and other equipment or accessories that are not manufactured by Composite Research, whether the same is or is not warranted by such other manufacturer;

- Damage to, breakage of, or leakage around any windshields, hatches, or apertures;

- Any canvas, zippers, vinyl, upholstery, plastic, or fabric components;

- Mold (Pink Mold, Yellow Mold, etc.) on upholstery or cushions. (Mold damage covered 9 months from Day of Delivery to Dealer)

- Discoloration, oxidation, bleeding, or corrosion of any stainless steel or other metal products;

- Wind Shields (Glass or Lexan);

- Engine and accessory removal and de‐rigging or re‐rigging.

- Any Hull, component, or product that has been subject to unreasonable use, tampering, misuse, abuse, neglect, negligence, mishandling, vandalism, fire, riot, war or Acts of God. A boat powered or loaded in excess of the maximum limits as stated on the U.S. Coast Guard capacity plate attached to each boat is considered misuse;

- Any boat, or component or part thereof, that has been used for Commercial Purposes, racing purposes, or has otherwise been operated contrary normal recreational purposes or contrary to any applicable law (for purposes of this Limited Warranty, the term “Commercial Purposes” shall mean the usage of any boat more than fifty percent (50%) for revenue producing

or other business purposes); - A boat, or component or part thereof, that has been overpowered according to the maximum recommended engine horsepower specified on the capacity plate attached to the boat;

- Repair or attempted repair by unauthorized persons or any boat which shall have been repaired or altered in any way so has to affect its use or operation.

- The failure of any part, area, or component of the boat to be dry, whether or not the same was represented as “dry”;

- Any representation relating to the speed or weight of any part or component of the boat;

- Normal wear and tear maintenance items, including, but not limited to, filters, bulbs, batteries, bungees, anchor rope, trailer finishes, tires, brakes, bearings, and lights;

- Damage caused by the improper fitting of a boat to a trailer, by use of a roller type trailer, or by not following the Composite Research, Inc. Trailer Guidelines ( a copy is obtainable from your independent Composite Research Dealer or from Composite Research online at https://www.criboats.com/knowledge‐base/ , or caused by failure to use proper boat

tie downs. - The cost of de‐rigging and re‐rigging any parts or accessories, hardware, engines, fiberglass component parts whether original equipment or installed originally by the Dealer or the Owner. The Owner will be responsible for the cost of rigging removal and rigging additions.

- Any defect or repair requiring redesign of the boat, except pursuant to the recall provisions of the United States Federal Boat Safety Act of 1971 or the recall laws of any other foreign jurisdiction;

- Dealer preparation, cleaning, final adjustments and alignments in preparing the boat for delivery or commissioning; or

- Any act of God or force majeure.

The following items are warranted by their respective manufacturers and are not warranted by CRI:

- Engine, Engine controls, Key Switches and Engine wiring harness.

- Batteries or Chargers, Depth Finders, Radios, GPS Systems, Stereos or other electrical systems.

- Trolling motors, Trolling Motor Controls or Electrical Connections, Damaged caused by Trolling Motor Mounting to deck or subsequent damage caused by Trolling Motor impact when in use

Procedure for Warranty Repairs

- The boat must be returned to the selling independent Composite Research Dealer, for an initial inspection. In the event the selling independent Composite Research Dealer has ceased to do business or you are traveling or you have moved to a different locale, warranty inspection may be performed by any authorized independent Composite Research Dealer. The address concerning warranty matters is Composite Research, Inc. 6131 Sundance Road, Blackshear, GA. 31516.

- You must present your registration card or original sales receipt to the independent Composite Research Dealer to verify the boat is still in warranty.

- The independent Composite Research Dealer will examine the boat to determine if, in his opinion, a warrantable defect exists. If a warrantable defect appears to exist, Composite Research will require the boat hull to be returned to the factory, or at its sole option, an Authorized Dealer, for repair or authorize repair of a boat hull that is found to be defective. For repairs performed other than at the Composite Research factory, a written authorization form must be received and approved by Composite Research prior to any work being performed.

- All transportation, haul out, shipping and/or delivery charges are to be paid by the boat owner.

- All removable items, including but not limited to electronics, radios, gear and tackle, batteries, personal items, etc. must be removed by the owner prior to shipment to the Composite Research factory. Neither Composite Research or it’s Independent Dealer will be responsible for any loss of personal items not removed from the boat hull prior shipment to the factory.

- If boat hulls are repaired or replaced under the terms herein, the terms of this limited warranty shall cover such boat hull for a period of ninety (90) days from the date of repair or replacement or until the end of the original Limited Warranty period, whichever is later.

Limitations and Exclusions:

Composite Research shall not be responsible for any incident or consequential damages of any sort or nature including but not limited to personal injury, property damage, loss of use, time, or income. Some states do not allow the exclusions of damages so the foregoing may not apply to you.

The remedy available under this Limited Warranty is non‐cumulative in nature and is limited to repair or replacement, at Composite Research sole option, of the boat hull which is returned to a location approved by Composite Research, and which it’s examination discloses to its satisfaction to be defective. This warranty gives you specific legal rights. You may have other rights that vary from state‐to‐state.

Composite Research reserves the right to change the design of any boat without obligation to modify any boat previously manufactured. This warranty constitutes the entire agreement between Composite Research and the owner. Composite Research does not assure nor authorize any person other than its corporate officers to assure any obligation on its behalf.

Sole Remedy

Statute of Limitations

Owner’s Obligations

Assignment of Component Warranties

Governing Law, Modifications, and Severability

Inshore vs Offshore Fishing: The Real Deal

Call it what you will, blue-water fever, inshore, flats, we all have our preferences when it comes to our favorite species of fish and the waters we enjoy. As for how we get there, the styles of boats are endless from small skiffs or bay boats to large sport-fishing battle wagons. What might not be clear to a would-be angler, what are the real, down and dirty differences between offshore and inshore fishing?

Operator’s Guide: Stepped Hull Boats

Purpose

The intent of this document is to provide a clearer understanding of the operational differences between a stepped-hull vessel and a traditional mono-hull style boat. Specific attention is provided herein to the uses and adjustment of engine trim. As such, this guide assumes that the reader and/or boat operator has experience using throttle-based engine trim controls and is performing the recommendations herein under favorable weather and water conditions. Towards this end, any reference to “trim” or “trimming” within this documents speaks directly to the outboard engine’s angle in the water, not the use of exterior-mounted trim tabs.

Benefits of a Stepped Hulls

A stepped hull design generally grants a boat with a larger degree of deadrise the ability to ride flatter in the water with a cruising height of approximately 3° bow up attitude. The inclusion of steps assist the vessel in achieving more speed, with less horsepower, and improved fuel efficiency versus traditional hulls with the same horsepower. Speaking purely on physics, when on plane, a stepped hull decreases the total wetted surface due to less contact points with the water and thereby lowers overall drag. Given this, while in a turn, the reduction in drag will produce a smaller wake. The end result, a stepped hull will generally be more efficient, use less fuel, and obtain a higher top-end speed.

Default Trim Position at Cruise

When operating a stepped hull, engine trim should be set to 50-60% out for maximum efficiency as this puts the cavitation plate parallel with the water. In contrast, a traditional hull would run with an approximate 25% trim.

Deceleration

When backing off the throttle and as the boat begins to settle, start trimming your engine into the zero-trim position. The zero-trim position should be consider the default and used for the starting point for acceleration.

Accelerating to Plane

To rise up to plane, increase the throttle briskly and begin trimming the engine outward within just a few seconds of acceleration. As speed increases, the operator should continue to add trim until reaching the 50-60% position and an approximate cruising speed of *30 to 40 MHP. *This will vary from vessel to vessel and engine horsepower.

Turning On Plane

Once on plane, trim the engine ‘as needed’ until the steering feels light and responsive. Understanding ‘feel’ is subjective, it is recommend taking multiple test runs to determine where your boat performs best.

Eliminate Bow Lift

Ideally, as the operator adds speed and trim simultaneously, the vessel will hold a 2° to 3° attitude. Translating from degrees to inches – from the helm position and looking forward, the forward-most point of the boat could be expected to rise approximately 6”. When properly trimmed, the vessel should not exhibit any bow lift on the hole shot.

Trim & Turning

With a mono-hull, it’s common to trim the engine inward (tucked in) to increase bow bite. In contrast, a stepped-hull should stay closer to the normal running position of 50-60% as not to dig into the water. The reason for this is during harder turns, the steps will lose their air induction within the inside hull vents and thereby increase wetted surface and cause drag. When this occurs, the operator should correct by adding throttle and keep the bow up.

Trim Tabs

Unless the vessel is experiencing wind induced heel, a need to correct a ballast heel, or the need to create a heel in windblown spray conditions, the operator will rarely have a need to use externally mounted trim tabs.

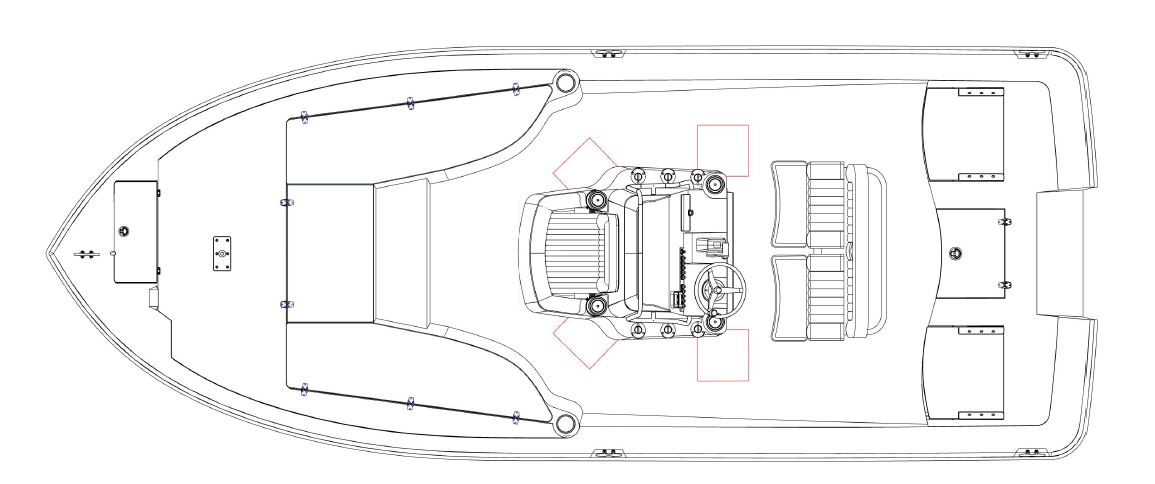

I’m installing a T-Top. Where are the aluminum plates under the deck of the FX21 Bay Sport?

The Aluminum plates need for installation are 12”x12” x1/4”. The placement of the plats can vary by up to 1” during the construction process.

During factory installation, T-Top foot pads are glued and sealed to the deck with 5200 or similar compounds. To further secure the part to the deck, we recommend a screw Length of 2” into the Aluminum, 1-1/2” if into the general laminate. Finally, the deck laminate schedule at the Aluminum plates is typically 1-1/2”.

Finally, a toggle bolt is not recommended in the subject areas due to limited clearance under the deck.

Notice:

The attached document and information within this article are to be used by marine professionals who plan to install a T-Top or Hard Top on the Sea Born FX21 Bay. Please note that adding third party parts and accessories may void your manufacturers warranty. As such, we strongly recommend you consult your local Composite Research, Inc. dealer prior to installation.

Still Unsure?

If you’re still undecided if a T-Top is right for you, be sure to check out our post, Boat Buying 101: Should I Add a T-Top to My New Boat?

What is the fuel capacity of the Sundance SV-171?

Approximately 34 Gallons

In Loving Memory – Brad Miller

It is with great sadness that we announce the passing of one of our longest standing, well-known employees, Mr. Brad Miller. Brad, an 8+ year member of our sales and territory management, passed away during the evening hours of January 10th, 2018 at home in Waycross, Georgia.